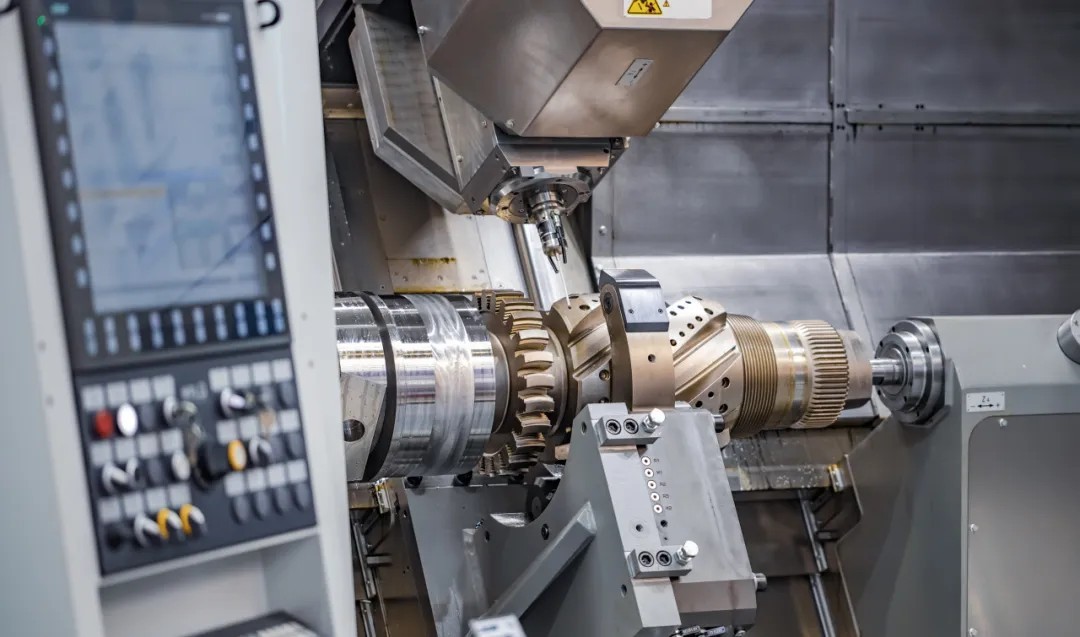

Kwimveliso yanamhlanje, amaziko oomatshini be-CNC zizixhobo ezibalulekileyo, kwaye ukusebenza kwawo kuchaphazela ngokuthe ngqo ukusebenza kakuhle kwemveliso kunye nomgangatho wemveliso. Njengenxalenye yolawulo oluphambili lwamaziko oomatshini be-CNC, ukuthembeka kunye nokuzinza koqhagamshelo lombane lwangaphakathi kwiikhabhathi zombane kubalulekile.IWAGOIibhloko zesiphelo ezifakwe kwi-TOPJOB® S zidlala indima ebalulekileyo kwiikhabhathi zombane zeziko lokulungisa i-CNC ngetekhnoloji yazo ephucukileyo kunye nokusebenza kakuhle.

Imingeni yeekhabhathi zombane zeziko loomatshini be-CNC

Ngexesha lokusebenza kweziko loomatshini be-CNC, iikhabhinethi zombane zijongene nemingeni emininzi. Kukho izinto ezininzi zombane zangaphakathi kunye neentambo ezintsonkothileyo, kwaye izisombululo zonxibelelwano ezisebenzayo ziyafuneka ukuqinisekisa ukuchaneka nokuzinza kokudluliselwa kwesignali; kwangaxeshanye, ukungcangcazela, impembelelo kunye nokuphazamiseka kwe-electromagnetic kunokuveliswa ngexesha lokusebenza kweziko loomatshini, nto leyo efuna ukuba iibhloko zesiphelo zibe nokumelana okuhle kokungcangcazela, ukumelana nempembelelo kunye nokukwazi ukulwa nokuphazamiseka ukuqinisekisa ukuthembeka konxibelelwano lombane. Ukongeza, ngophuhliso oluqhubekayo lwetekhnoloji ye-CNC, iimfuno zokunciphisa kunye nobukrelekrele beekhabhinethi zombane ziya ziphakama, kwaye iindlela zendabuko zocingo kunzima ukuhlangabezana nezi mfuno.

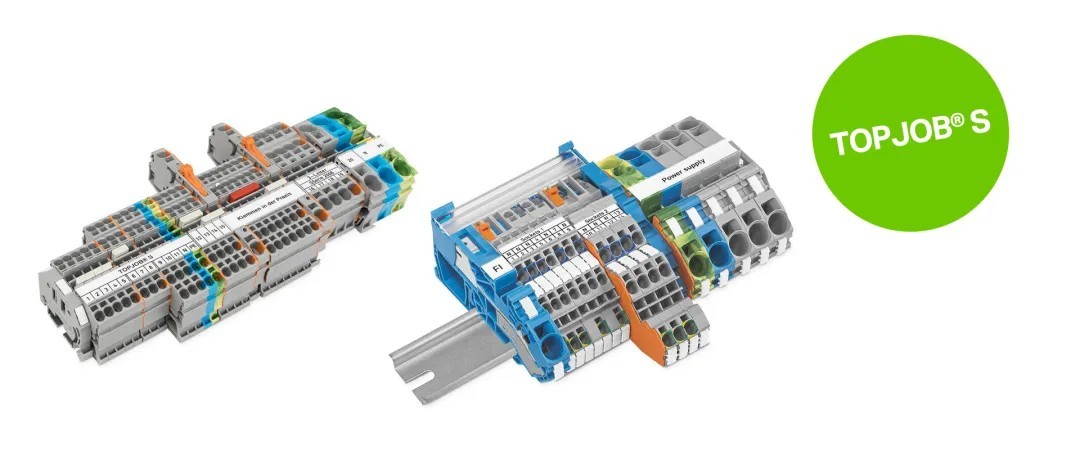

Iingenelo zeebhloko zesiphelo ezifakwe kwi-WAGO TOPJOB® S

01 Uqhagamshelo oluthembekileyo noluzinzileyo

IWAGOIibhloko zesiphelo ezifakwe kwireyile ye-TOPJOB® S zisebenzisa itekhnoloji yoqhagamshelo lwe-spring clamping, esebenzisa amandla e-elastic espring ukubopha intambo kwi-terminal. Ngexesha lokusebenza kweziko le-CNC machining, intambo ayizukuwa nokuba iphantsi kokungcangcazela okukhulu kunye nokuchaphazeleka.

Umzekelo, kwezinye iziko zokusika i-CNC ezisebenzisa isantya esiphezulu, izixhobo zomatshini ziya kuvelisa ukungcangcazela okukhulu ngexesha lokusebenza. Emva kokutshintshela kwiibhloko zesiphelo ezifakwe kwi-WAGO, ukuthembeka kwenkqubo yombane kuphuculwe kakhulu, kwaye inani lokuvalwa kokugcinwa liye lancitshiswa kakhulu.

02 Ukufakela nokulungisa lula

Abasebenzi kufuneka bafake ucingo ngqo kwisiphelo ukuze bagqibezele uqhagamshelo, ngaphandle kokusebenzisa izixhobo ezongezelelweyo, nto leyo egcina ixesha lokufakelwa kweentambo. Ngexesha lokufakelwa kunye nokuqaliswa kwekhabhinethi yombane yeziko loomatshini be-CNC, olu phawu lunokuphucula kakhulu ukusebenza kakuhle komsebenzi, lunciphise iindleko zokulungisa kunye nexesha lokungasebenzi.

Umzekelo, xa kutshintshwa isenzi kwikhabhathi yombane, kusetyenziswa iibhloko zesiphelo ezifakwe kwi-WAGO TOPJOB® S, abasebenzi banokususa ngokukhawuleza baze baphinde baqhagamshele iingcingo, ukuze izixhobo zikwazi ukuqala ukusebenza ngokukhawuleza.

03 Uyilo oluncinci lugcina indawo

Uyilo oluncinci luvumela ukuba kubekho iindawo ezininzi zonxibelelwano kwindawo encinci. Oku kubaluleke kakhulu kwiikhabhathi zombane ze-CNC machining centre ezinesithuba esincinci, njengoko kunokunceda ekufezekiseni ulwakhiwo oluncinci nolufanelekileyo lweentambo kunye nokuphucula ukusetyenziswa kwendawo yekhabhathi yombane. Kwangaxeshanye, uyilo oluncinci lukwalungele ukutshatyalaliswa kobushushu kwaye lunciphisa umngcipheko wokonakala kwezinto zombane ngenxa yokushisa kakhulu.

Umzekelo, kwezinye iindawo ezincinci zoomatshini be-CNC, indawo yekhabhinethi yombane incinci, kwaye uyilo oluncinci lweebhloko zesiphelo ezifakwe kwi-WAGO TOPJOB® S lwenza ukuba iingcingo zibe lula ngakumbi kwaye luphucula nokuzinza kwenkqubo yombane.

Iibhloko zesiphelo ezixhonywe kwireyile zeWAGO TOPJOB® S zibonelela ngezisombululo zonxibelelwano lombane ezisebenzayo nezizinzileyo kwiikhabhathi zombane zeziko le-CNC machining, kunye neenzuzo zazo ezifana nonxibelelwano oluthembekileyo, ukufakelwa nokugcinwa okulula, ukuziqhelanisa neemeko ezinzima, kunye noyilo oluncinci. Njengoko iteknoloji ye-CNC machining iqhubeka nophuhliso, iibhloko zesiphelo ezixhonywe kwireyile zeWAGO ziya kuqhubeka nokudlala indima ebalulekileyo ekuncedeni imboni yokuvelisa ifikelele kwinqanaba eliphezulu le-automation kunye nemveliso ekrelekrele.

Ixesha leposi: Matshi-14-2025